» Technical consulting and inspiring development initiatives

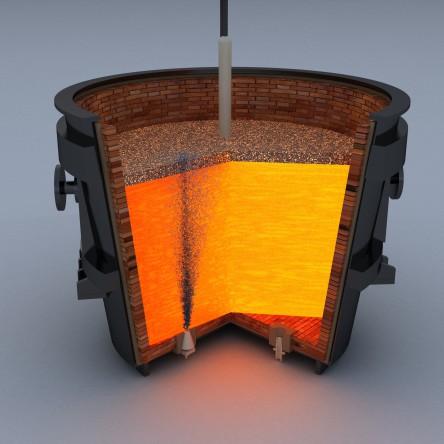

» In-service monitoring of refractory products

» Health monitoring and wear analysis of refractory materials in specific thermal processing units, down to separate temperature zones

» Engineering consulting and performance of refractory lining maintenance and overhaul in thermal processing equipment (furnaces, ladles, etc.)

» Market analysis

» Maintenance of databases with applied refractory materials

» Organisation and delivery of training in operation and maintenance of refractory lining servicing equipment, like gunite guns, handling fixtures, rendering machines, and more

» Servicing of refractory lining servicing equipment